The HVAC refrigeration cycle is really just the simple process of replacing cool air in your house with heated, conditioned air at the end of the day. There are many parts of the system, but perhaps the most important part of all is the compressor. It is where all the work for cooling and conditioning takes place. It takes two stages to complete this important job, namely Evaporative Cooling and Condensation Removal. By the end of this article you should have a good idea of how the entire system works. You will read more here and learn all about how the entire system works..

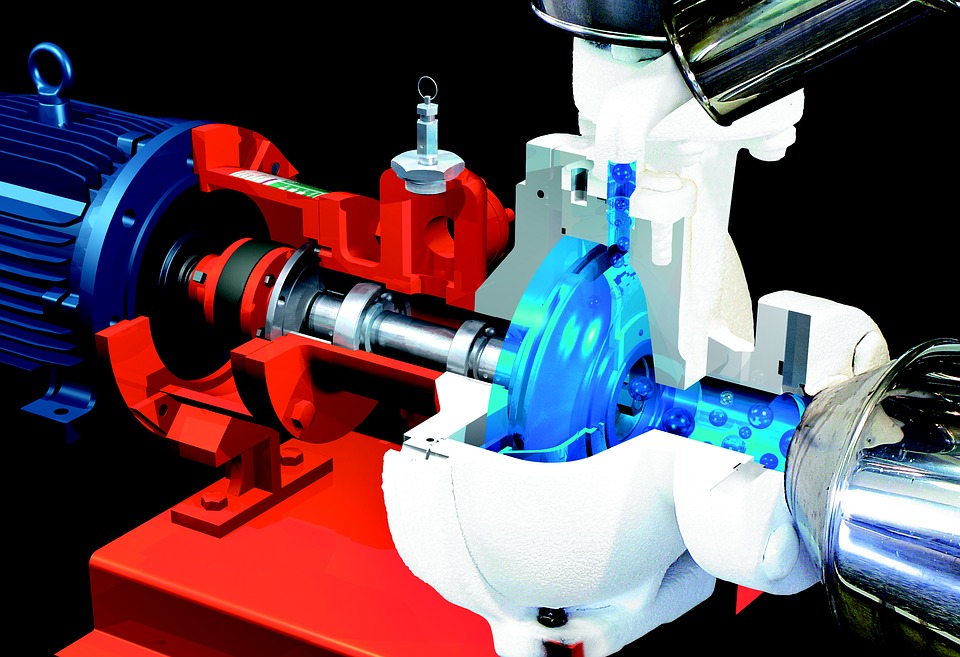

Compressor: In the HVAC refrigeration cycle, the compressor compresses air in order to lower its pressure. A fan pushes the compressed air through a tube to a condenser. Here is where things get interesting: the heat from the condenser is captured by the refrigerant gas, which is then released into the room. This is known as the solar thermal power of the system. As the warmed air exits the condenser, it is cooled by the return air filter. The cooled air is then released into the rooms, creating energy savings.

Condensation Removal: On the exterior of the house, we may see water condensation forming. This is because the heated air outside of the house is cooled by the high-pressurized air in the house. This water is removed from your walls, and voila!

Solar Thermal Energy Conversion: On the inside of the hvac refrigeration cycle, we have the heat of the refrigerants escaping, being used by the condenser coils to heat water, and the refrigerant gas escaping as either cold or hot water. The process of converting this heat into energy is called solar thermal energy conversion. During the summer months, this energy source is very effective. However, in the wintertime, it is ineffective.

Efficiency upgrades: There are many ways in which the HVAC refrigerant cycle can be made more efficient. You can upgrade your compressor, or you can change your condenser, or perhaps change your whole air conditioning system. As you can see, upgrading your HVAC system is not too difficult and costly, considering the energy savings you will see over time. Click at https://www.hvacknowitall.com/blogs/blog/595767-the-refrigeration-cycle-explained for more information about the HVAC refrigerant cycle.

Vapor compression: Just like the solar thermal energy conversion, a vapor compression system can also be installed easily. In this method, a vapor compressor forces cold air into hot air, and then sends the hot air out of the house via an exhaust. This is not only highly efficient, but it is also pollution free. Just like the solar thermal cycle, there are also ways to make the vapor compression more efficient such as increasing the compressor’s efficiency and the size of the air flow. Find out more details in relation to this topic here: https://en.wikipedia.org/wiki/Refrigeration.